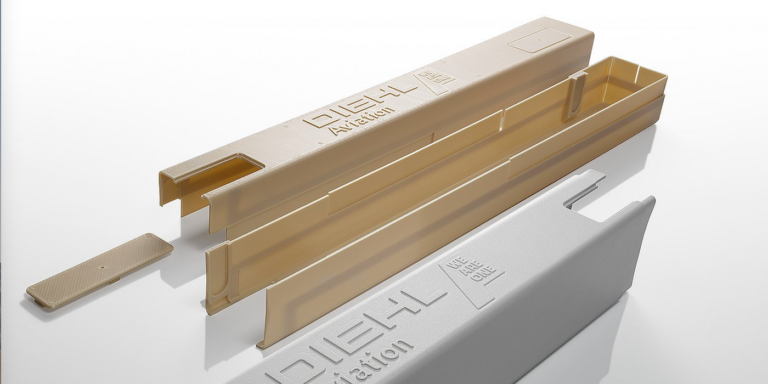

At a time when 3D printing technology is continuing to progress, and its implementation in aerospace is growing, Diehl Aviation has delivered its largest, fully 3D-printed part for passenger aircraft to date. The part in question is a curtain comfort header – a complex enclosure for the class divider curtain rail – for installation on a Qatar Airways Airbus A350 XWB. The module was manufactured using the fused deposition modeling (FDM) technique and measures 1,140 x 720 x 240mm.

The project took 12 months from initial concept to EASA certification and delivery, and Diehl Aviation has stated that the new production method for the curtain header solves several problems. These modules are usually formed from numerous layers of laminated fiberglass, each of which required its own individual, complex aluminum tool. Incorporating further functions into the module added, such as the integration of cable channels, emergency escape route signage or specialized retaining clips presented further work and complexity. However, when produced using FDM, the complete module is comprised of up to 12 component parts – all produced by a 3D printer and simply glued together when complete. This new production procedure has made many of the old, individual tools required to manufacture these parts redundant.

Indeed the project has showed such benefits that Diehl Aviation will now only produce curtain comfort headers for the A350 XWB using the 3D printing method. This procedure offers several advantages for customers, including shorter production processes and lead time reductions for airlines under pressure for quick turnaround times. According to Diehl, the parts themselves require less reworks and can easily be removed for repairs or replacement, contributing to shorter waiting times during repair works. Also, the modules can easily been customized for retrofit solutions. Meanwhile passengers benefit from precision-made parts, which lead to dampen noise and allow better integration in the cabin.