Kaman UK, a supplier to the aerospace industry, claims to have developed a process that ‘significantly’ reduces development lead times for the design and manufacture of complex mould tools for composite parts manufacturing.

The company has implemented ‘springback’ modelling techniques, which reduce the time required for manufacturing refinement of complex composite mould tools and in turn reduce entry into service times and costs for the end user. A development phase could typically take around 12 months, but with the use of theoretical modelling, this time can be reduced by up to 30%.

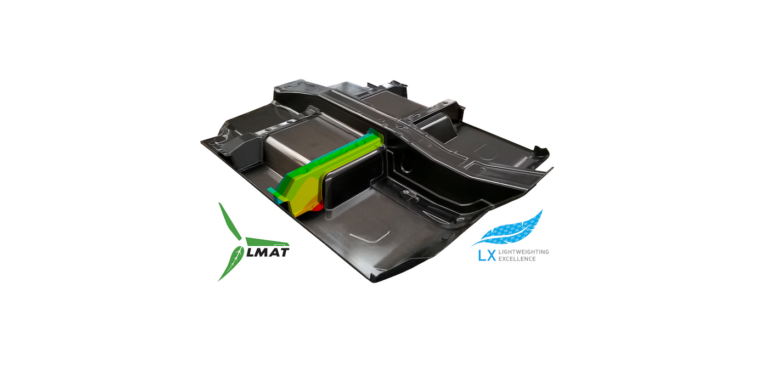

The company has incorporated LMAT’s mathematical modelling software to accurately predict and analyse the spring and twist of a carbon fibre composite parts during manufacture, and compensate mould tool surfaces accordingly to ensure design parameters are met.

This approach removes the risk of manufacturing moulds which have to be subsequently modified once initial parts have been manufactured, and foreshortens project development times.

According to Kaman UK, when a composite mould tool is manufactured, its surface features don’t always define the composite part characteristics required due to certain factors. Acute angles and curvature, part characteristics such as cross-sectional thickness, the fibre architecture of the composite materials and thermal stresses inherent in the composite curing process all contribute to this variation.

Historically, this has necessitated that the mould tool is re-cut, adjusted or even remade based on data acquired during the part manufacturing development stage. This is both a costly and time-consuming aspect of new part introduction.

Initial springback values of 4° away from nominal are not uncommon with traditional ‘trial and error’ manufacturing techniques for complex parts. The use of LMAT modelling enables these values to be predicted on a part-by-part basis, thus ensuring Kaman can design and manufacture the required composite mould by accurately configuring the tool surface during the initial manufacturing process without the need for subsequent modification.

James Scholfied, Kaman UK’s business development director stated, “We are capable of enabling the use of new mould tools in weeks rather than months, which is removing a lot of risk and cost for us and making new product introduction much simpler and shorter for our customers. This is a huge step forward in composite manufacture development and greatly increases the ability of Kaman to assure the mould tool and therefore the part is right first time.”

Kaman UK has also made long-term investments in its in-house metallic and composites capabilities along with a £1million investment in a surface treatment line that achieved NADCAP approval status last year. This enables the company to offer a full service ‘one-stop-shop’ for fully integrated structures.

Tomasz Garstka, LMAT’s managing director added, “Distorted components can cause major problems during aircraft assembly. However, utilising the benefits of LMAT’s advanced numerical tooling design workflow process it provides compensated tooling geometries right first time. For a number of our customers we have supported them in significantly reducing overall product cost as well as improving in-service performance”.