Commercial airlines face many commercial pressures on their operations, which impacts the design of aircraft cabins. Airlines are working towards decarbonising their operations under the Net Zero by 2050 commitment, which will require further innovations in cabin structures and materials in terms of lightweight and sustainable design. There is also currently a shortage of staff – crew, passenger services and maintenance – which is impacting airline performance. Aircraft cabin designers must think ahead to simplify work for ever-busier cabin crews and reduce the maintenance requirements of cabin components.

All of this suggests that simplifying cabin interior design might be a timely exercise. But as those we spoke to for this article point out, it is hardly a simple task. One of aircraft interior design’s most significant challenges is cutting excess without harming durability, safety and passenger satisfaction. But aviation handles challenges well.

The Finnair AirLounge business-class seat, designed by Collins Aerospace, PriestmanGoode and Tangerine, and a finalist in the 2022 Crystal Cabin Award, is an inspiring example of the future of ‘bare essentials’ design. This unique seat/bed/settee/sofa combination represents a new step toward simplification in a part of the cabin that has grown increasingly complex in recent years with the introduction of business class suites as the higher service standard.

All Nippon Airways (ANA) also recently unveiled ‘The Room FX’, its new business-class seat for the Boeing 787-9, which the airline says is “the world’s largest seat in its class on a mid-sized aircraft”. Again, the seat has a pre-reclining function that transforms the backrest into a sofa-like space in which passengers can relax in a variety of positions, aided by the more curved lines of the backrest area.

The push to reduce the weight of cabin components and optimise design has been ongoing. Because the airline economy has always been challenging, airlines have pushed vendors to reduce the weight and cost impact of their products for decades, going back even before this author was on the cabin interiors shop floor in 1994.

So how much is there left to do? Can we move to even simpler structures and further reduce weight and costs? Should we? Can we do so without violating the regulatory standards for passenger safety and making passengers feel they are getting less for their ticket price?

The challenges and opportunities of reducing aircraft seat weight

In speaking with cabin designers and manufacturers on this topic, the consensus seems to be that there is nothing new under the sun, yet opportunities still lie ahead.

As Ben Orson of Orson Associates says, “The idea of reducing weight is not new. It has been a priority since the Wright Brothers put a plane in the air. It’s been reframed around sustainability recently, and rightly so. But if you’re looking to reduce the mass of what’s in the cabin, fundamentally this isn’t uncharted territory. In terms of mass production, all the low-hanging fruit has been plucked before you start sacrificing things.”

Those sacrifices may include passenger experience, branding, and maintainability. “There is always going to be some sort of a trade-off if you want to pull a lot of weight out,” Orson adds. He suggests that one framing of simplification in the cabin may not be about re-engineering structures alone, but rather about ensuring that all waste is cut from the cabin.

“There are many things on board that are not used by passengers, such as amenity kits, headphones, food and packaging. There’s an awful lot of waste,” says Orson.

Of course, airlines may hesitate to cut too many of these items from the cabin out of concern that it might lead to customer backlash. It has always been tricky to take away something passengers expect. Robert Crandall’s historic 1980s trick of removing one olive from each American Airlines salad saved US$40,000 a year, as the airline paid its inflight caterers based on the number of ingredients used in the salad.

However, the move also resulted in the threat of boycott from the ‘olive producers lobby’, which was ultimately resolved by introducing the onboard Martini – shaken or stirred, with olives. There will always be a risk and a price to pay for cutting costs.

Cut weight, not the passenger experience

The question is whether design can enhance the passenger experience while cutting excess elements. The Finnair AirLounge seat suggests there might be opportunities. While the seat structure itself is leaner than seats with actuators, stripped of such complexities, the simple design also gives passengers more room to move around and greater flexibility on how they enjoy their journey, which is a valuable gain.

As Matt Round from Tangerine, explains, the thinking behind the design was to make passengers feel at home on the aircraft. “We set about trying to turn this vision of Nordic freedom into a cabin experience,” Round says.

“There are some very subtle changes in the profile and form of that seat. That means that when you move your body into different positions, you get a different feel from how the seat supports you,” explains Round. “And there is a lot of emphasis on creating a private-feeling space without adding a door. Because, if you put a door in, that takes out a whole lot of space that the person could be relaxing in.”

Delivering the privacy of a suite without a door posed regulatory challenges for the AirLounge because there are limits to the permitted height of the shell around the seat. The designers resolved this by focusing on contours to make the passenger feel “cocooned in their space”.

“When you’re on the inside, that shell is painted all the way around on the inside, with soft upholstery and beautiful fabric,” Round says. “It’s a cosy nest feel, and you can’t see much of the outside world once you’re sitting inside it.”

New opportunities to save weight are on the horizon

Matt Round agreed with others we spoke to, who pointed out that the industry has already considered many angles on engineering and designing optimum structures, but that doesn’t mean we’ve reached the limits. As technologies and materials evolve, more opportunities are created every day.

“I think the amount of stuff you must go through to get to simplicity is significantly greater than what you have to go through delivering something complex that might do the same job,” Round points out. “I think there is beauty in simplicity, and a kind of mass intelligence in simplicity. It’s about figuring out what the essential ingredients are and what things you can strip away. It’s a real challenge. You have to think back to some things you thought were intelligent and simple.

“And when you start using it with consumers, you realise they see something in the way, so there’s another level of synthesis. That’s why iteration is important – allowing the time to build an idea, test an idea, and iterate. Then you get to simplicity. I don’t think there’s ever that ‘light bulb’ moment. That doesn’t exist. It’s about everything you do leading up to that moment.

“That massive exploration just gets to the point of having all the information and synthesising the right way to get to that solution. That’s generally with input from lots of people. It’s not one person’s ‘magic light bulb’ moment, when they just happen to have an idea in a restaurant and draw on a napkin. It’s about hard work from lots of people,” explains Round.

That iterative process may discourage a ‘bare essentials’ design strategy for aircraft cabin components. Project deadlines and budgets rarely allow for repeated iterations. If anything, the trend has been to simplify the timeline and cut costs by setting specific model baselines and allowing for a small subset of variations for branding.

Manufacturing challenges

There’s a rationale for that approach in the manufacturing process as well. Manufacturing the materials and components of aircraft interiors requires special tooling, thorough testing, including destructive testing, detailed documentation, and extensive training of the staff who will build the product.

We spoke to two figures from Collins Aerospace about such hurdles of simplicity: Ray Foley, director of advanced systems & demonstrators, and David McConnell, associate director of research. Foley explains that Collins is investing in new design thinking and has set up a Sustainability Taskforce to develop products that help airlines reach their decarbonisation goals.

In addition to working to reduce carbon footprints, Collins is exploring more effective lifecycle management of cabin components. The team is also looking at Circular Economy practices (as is Safran Seats), with key aims being reducing, reusing and recycling. When the Collins team considers sustainability, they also see customer sustainability as a pillar of their strategy. That is what their customers and the aviation industry will need during the transition to a more sustainable business model.

New composites and technologies can facilitate the manufacturing of unique structures, which might resolve some of the challenges of multiple design iterations. For example, McConnell gained insights from Collins’ participation in the European SuCoHS (Sustainable and Cost Efficient High-Performance Composite Structures Demanding Temperature and Fire Resistance) project. The project also explored design methods, and investigated topology optimised structures and other ways to make the lighter weight more sustainable, including using bio-based materials.

“We also looked at advanced manufacturing methods and automated fibre placement,” McConnell explains. One of the learnings from this project is that it is possible to develop a cost-efficient product that is also more sustainable, with more efficient manufacturing methods, which also reduces the carbon footprint of component production.

The growing role of digital design tools

For iterative design, McConnell says that modern digital design tools could contribute significantly. “You consider all the elements together – how materials may affect a key part. Digital engineering methods and simulation techniques can [confirm how each change affects] a KPI (key performance indicator). You can start to tackle all of these factors together as you can get cost efficiency, high performance, and meet passenger expectations, all with sustainability at the same time.”

“We want to get to the point where we’re doing much of our [sustainability] design up-front for concepts,” Foley states, adding that it isn’t always about everything being as lightweight as possible. “Sometimes when you make something lighter, you might make something else a little heavier, for durability.

“That will trade off with a CO2 benefit. We do try to do those kinds of trade-offs across multiple disciplines. But it’s a Pareto front,” he adds, referring to designers restricting their attention to a set of efficient choices, and making tradeoffs within this set, rather than considering the full range of every parameter.

“You’re trying to get to some optimum across multiple different dimensions. The other piece that we’re growing is the digital product lifecycle. This accelerates how we get things to market, which is important for sustainability. Because the sooner you can get them added into the market, the better,” adds Foley. “From design through to R&D, design, production, all the costs of using the same models, and then even during the life of the part.”

Collins is also exploring diagnostics, including smart-cabin systems that verify durability in the lifecycle of parts.

The durability benefits of simplified aircraft seat design

One of the aims of sustainable design is to reduce the failure rate and lengthen the service life of aircraft interiors. As Peter Tennent of Factorydesign states, “I think sustainability is the accumulation of lots of small gains, with the use of different materials in different parts of the product.”

Like others, Tennent defines ‘essential’ design as being durable and certifiable.

“You’ve got very stringent requirements. If you take too much away, you’re going to lose strength and reliability,” he says. “There’s no point in having a sustainable product that weighs 5kg less, if it falls apart every five minutes. You lose that advantage by having to spend money maintaining the product. So there are lots of careful balances that we have to address when we look at these things.”

Daniel Baron, founder of Lift Aero Design, points to an opportunity or perhaps even a need for more materials specialists to think of creative applications that can be sustainable and still deliver on brand identity and passenger experience.

“Lighter weight with enhanced durability and fewer parts sounds ideal, but will there be new issues?” asks Baron. “For example, the difficulty in piecing back together large structures that had to be separated to get them into the cabin. More noises are audible in seats – and louder – due to adopting a bare essentials approach, which is more pronounced now because engines have become so quiet.

“Another discussion is how to blend CMF into a structure to eliminate or lessen the need for decorative surface materials,” adds Baron. “That would help with parts simplicity, but would the aesthetics be attractive enough to communicate ‘safe and secure’ (i.e. ‘not a tin can’), as well as the airline brand’s unique personality and positioning? Concrete and metal are all the rage in cafe and boutique hotel design at the moment, complete with exposed pipes, but what works for ‘chill’ on terra firma would not necessarily work in the air.”

The flying public’s views of sustainable aviation

The up-and-coming generation, whom airlines will want to serve, may be more willing to make some concessions for the freedom to fly, although that view is still unproven. As Baron suggests, they are unlikely to want to see the raw interior of the aircraft, but they may be influenced to choose their flight based on the reputation of the airline for sustainability.

“A survey done by NATS, the air traffic control organisation in the UK, found that 70% of people agree that reducing emissions is the number one priority for aviation,” Orson states. “This was over and above things like making journeys shorter. Generationally, that percentage is only going to get greater.”

Orson also points to a 2020 UK CAA survey which found that 36% of respondents were willing to pay more for tickets on flights which had less of a negative impact on the environment. Again, that is only a theoretical booking and attitudes might shift at check-out.

Perhaps the next generation will see things differently. “I think there’s a generation coming through that will probably respect the leadership of an airline that was willing to look at sustainability and truly turned back on some of the amenities that are perhaps not relevant to them, though it’s possibly slightly utopian,” adds Orson.

“But suppose you’ve got a flying public willing to pay more for a more environmentally friendly flight. In that case, perhaps airlines could divert some additional potential revenue into the non-recurring costs needed to develop more lightweight products.”

The strongest argument for decarbonisation in the airline industry is image control and politics, and the industry has been a target of environmental activists for many years. It is an existential issue for the industry to ensure that it cares, and is seen to care, about the climate.

But there are other reasons to go for bare design thinking. It can spur innovations in new materials and manufacturing methods that will benefit the industry in the long run. It may also help airlines manage aircraft maintenance challenges and their fleet lifecycles.

“The march of technology is providing us with ways of making things lighter,” Orson adds. “We look at what we refer to as bionic design – a combination of technologies on the design side – topology optimisation, and generative design, which helps you create more optimised forms for structural efficiency.”

Other technologies include 3D printing, which can be used to create more complex, lightweight but resistant shapes, with little waste.

A few other ideas for simplified seating:

Style & Design’s ‘Moments’ concept

An oft-used adage in seat design is that the most comfortable position is your next position. This ethos was applied by French design studio, Style & Design, with a business-class concept that extends the seating space to create a range of sofa-like positions for sitting, lying and turning, without requiring extra cabin space.

The studio has found that typical long-haul business class seats with kinematics systems lead to passengers having their head, back, buttocks and legs always in contact with the same surfaces, creating pressure points, preventing muscle activation and blood circulation. Their solution is Moments, an active seating system that enables people to move freely within their seated environment, promoting movement, improving posture and activating core muscles.

The sofa-like design offers straight and multiple angled positions for solo, companion, lounging, reading, working and sleeping positions, with a two-piece legrest that fills the space in front to create a broad area that enables different postures. To reach the bed position they simply recline the lower backrest, which then opens up a head alcove, and then slide their body into the ottoman on one side before laying down their back and head into the opposite alcove.

The simple design is available from a 44in pitch, with weight minimised as Moments uses simplified kinematics, with just simple legrest deployments and a pivoting lower backrest required to reach a comfy bed position. This simplicity is claimed to save weight by 20 to 25% vs conventional seats and also frees up space to stow luggage in the space typically occupied by the kinematics and associated actuators and electronic boxes.

Style & Design says the design opens up new opportunities for airline customisation, as the unique seat geometry enables greater use of soft materials rather than plastic shells. A patent has been filed for the design, and Style&Design does not anticipate any certification issues. The design was a finalist in the Passenger Comfort Hardware category of the 2019 Crystal Cabin Awards.

Airbus’ CozyCorner concept

People enjoy luxuriating on a sofa at home, and would enjoy the same comfort in the air. In 2019 Airbus Interiors Services created a homey feel with CozyCorner, a long-haul business class environment that enables passengers to adapt their environment to their mood, whether sitting upright, lounging or lying down – just as they would in their living room.

Like Finnair’s AirLounge, the beauty of the CozyCorner design is its simplicity, consisting of just a single lightweight seat structure, complemented by a bench and a set of cushions, shaped to enable myriad seated positions. With a fixed bench build as a cabin monument and few mechanisms, weight is minimised, as are the associated investment and maintenance costs. The simple design also enables customisation options.

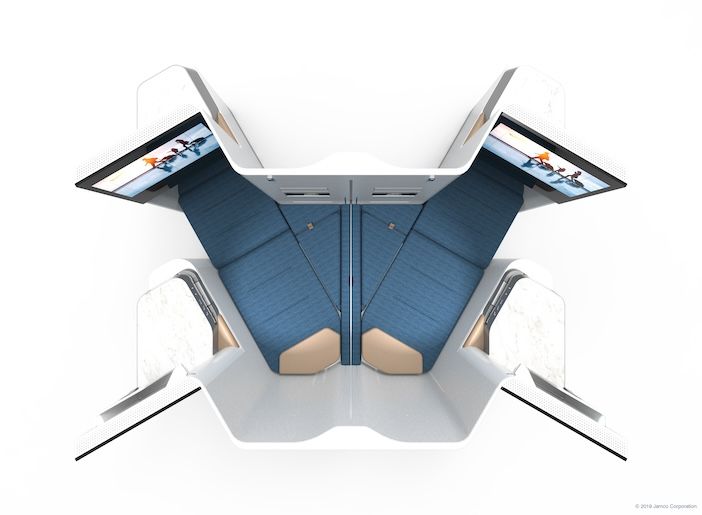

Jamco’s ‘Spread Your Wings’ concept

On the theme of simple, flexible passenger spaces, Jamco’s ‘Spread Your Wings’ design has a neat trick: When two people are travelling together in the centre seats, they can lower the privacy divider and share a flat space that is 2.5 times wider than a typical single aircraft bed.

Aside from being a great space in which to sprawl, the wing can also be used as a family bed for parents travelling with a baby, a place to do yoga, a space to spread out a board game or, if the door option has been specified, it can become a playroom for children.

Spread Your Wings is suitable for all widebody aircraft as a four-abreast (1-2-1) ‘window-ward herringbone’ layout, with aisle-facing centre seats and window-facing outboard seats, which enhances privacy throughout the cabin without high walls dividing the space.

Jamco has conducted tests on the seat for 16g dynamic load impact and will complete the certification process for the design once a launch customer has been secured, with a target of delivery within 18 to 24 months for that launch customer.