UK-based molding company, Rockwood Composites, has increased its manufacturing capacity by 50%, mostly for large aircraft components. The increased capacity is the result of investing in a third large press, built by Alderman Tooling in Plymouth, UK which will enable the company to produce more components up to a size of 2m x 1m, including aircraft interior door panels.

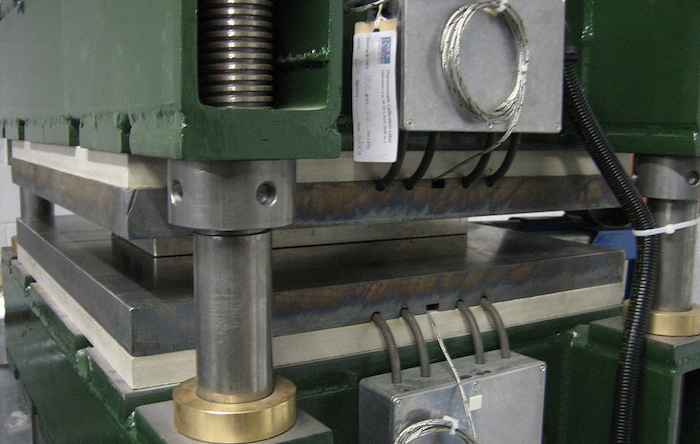

The presses, including this third large machine and and four smaller ones, use pressure and heat to cure composites material in order to manufacture complex composite components incorporating multiple elements and complicated geometries. The press molding process enables faster cycle times and produces high-quality components, which the company says require only a minimum of finishing.

Mark Crouchen, managing director of Rockwood Composites, stated, “The composites industry, especially the aerospace sector, is experiencing rapid growth, and we are seeing this with more enquiries and more orders.

“This new press is increasing our manufacturing capacity for larger components by 50% and we are looking forward to continuing to supply our customers with bespoke, prototype and volume composite components using both compression and bladder molding.”

According to Rockwood Composites the addition of the third large press may be timely, as the company is currently negotiating a “substantial contract” for aircraft interior components.